Model: XFS-180II

Description

XFS180II automatic granule and powder packing machine uses concise duplex output design. The max speed can up to160 bags/min. It is economic solution for high speed packaging for small bag.

Application

This HFFS pouch packaging machinery is widely used in the packing fields of food, pharmaceuticals, house chemicals, cosmetics, etc. And it is suitable for powder, granule product and liquid product.

Characters

1. With our single packaging solutions, the machine has been used in the pharmaceutical industry enterprises and a number of powder drugs with small bag packaging production workshop at a high speed.

2. Automatic granule and powder packing machine adopts full stainless steel configuration with vacuum feeding device and servo screw device.

3. Our scheme achieves products of the whole automatic line packaging solutions, such as health food, drug, drug infusion of particles, powder, etc.

4. At the same time, this scheme can also be extended centralized feeding system, dust removal system, on-line monitoring and box packing and other equipment.

5. The wrapping material is all kinds of multilayer heat-sealable films. Match with different filling head, the machine can pack powders, granule, liquids, and pastes in three side or four side sealed sachets.

6. HFFS pouch packaging machinery is a completely horizontal form fill seal packing machine, which is made up of bag-making, dosing, filling and sealing.

Technical Parameter

Model

|

XFS-180II Automatic Granule and Powder Packing Machine

|

Machine dimensions

|

3500 × 970 × 1500(L × W × H) mm

|

Weight

|

1500 kg

|

Electric supply

|

AC380V, 50Hz

|

Power

|

4.5 kW

|

Air supply

|

0.5 MPa

|

Air consumption

|

200NL/min

|

Packaging capacity

|

120 to 180ppm

|

Wide size

|

50 mm to 90 mm

|

High size

|

80 mm to 180 mm

|

Max filling capacity

|

100 ml

|

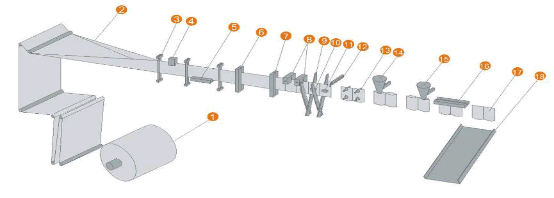

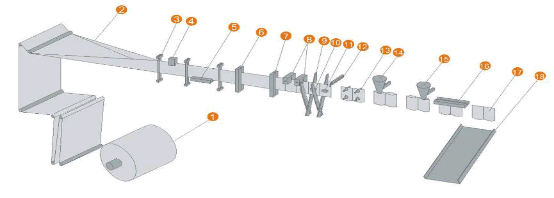

Packing Process of HFFS Pouch Packaging Machinery

1. Film unwind

|

4. Color scale detection

|

7.Vertical sealⅡ

|

10. Pouch clamp Ⅰ

|

13. Double pouch opening

|

16.Top seal

|

2. Bag forming

|

5.Bottom seal

|

8. Tear notch

|

11. Pouch clampⅡ

|

14. FillingⅠ

|

17.Finished product

|

3. Film guide

|

6.Vertical seal

|

9.Double cutting

|

12.Pouch pulling

|

15. FillingⅡ

|

18. Outlet

|