Description

Automatic peanuts sachet packaging machinery is a completely horizontal form fill seal packing machine, which is made up of bag-making, dosing, filling and sealing. Shanghai Xingfei Packaging Machinery Co., Ltd. is an integrated manufacturing enterprise with the ability to designing, developing, manufacturing, installing and commissioning of packaging machinery, automatic peanuts packing machine and automatic packing production line with various types and specifications.

Character

1. The sachet packaging machinery is controlled by PLC with human-machine interface display, which is easy to operate.

2. All the actions are driven by air cylinder, which improve machine’s efficiency, applicability and stability.

3. In packaging design, the automatic peanuts packing machine has upright and elegant appearance without liquid, powder around the end seal.

4. Servomotor control system is available for going down film, so that we can adjust dimension of film randomly.

5. With the high sealing strength and firm package, there are never the ragged edges. It is the ideal choice for packing foodstuff, pharmaceutical, cosmetic, pesticide, and feedstuff industry.

Application

Automatic peanuts packing machine is suitable for automatic packaging particular, powder materials like rubber, plastic particular, grain, wheat, seeds, milk powder, medicine. And it is suitable for powdery, granular and liquid products. Three-side or four-side seal of pouch is available with kinds of blanking devices to packing different materials.

Technical Parameter of Peanuts Sachet Packaging Machinery

|

Machine dimensions

|

1990×970×1390(L×W×H) mm

|

|

Weight

|

700kg

|

|

Electric supply

|

AC380V, 50Hz

|

|

Power

|

1.8kW

|

|

Air supply

|

0.5MPa

|

|

Air consumption

|

200NL/min

|

|

Packaging capacity

|

30 to 60ppm

|

|

Wide size

|

60 mm to180 mm

|

|

High size

|

80 mm to 225 mm

|

|

Max filling capacity

|

500ml

|

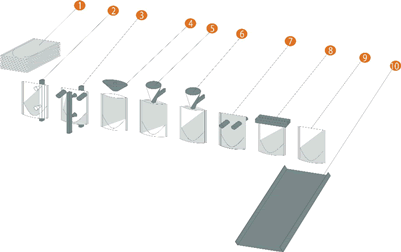

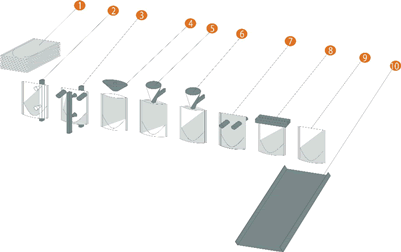

Packing Process of Automatic Peanuts Packing Machine

1.Premade pouch stack

|

3.Pouching opening

|

5. Filling1

|

7.Pouch stretching

|

9.Finished product

|

2.Flip-out pouch-packing unit

|

4. Air flushing

|

6. Filling2

|

8. Top seal

|

10. Outlet

|